Research & Development

At ROBATEL Industries we have an R&D laboratory which allows our research team to develop / constantly improve our solutions.

New solutions

We develop new solutions for :

- Shock absorbing materials.

- Neutrophage materials.

Our R&D department have developed a new range of products to improve the protective performance of our materials and their behaviour in the event of a serious accident (temperature resistance and M1 fire rating):

- PNT8™.

- Compound 23 ™ and Compound 24 ™.

FENOSOL™

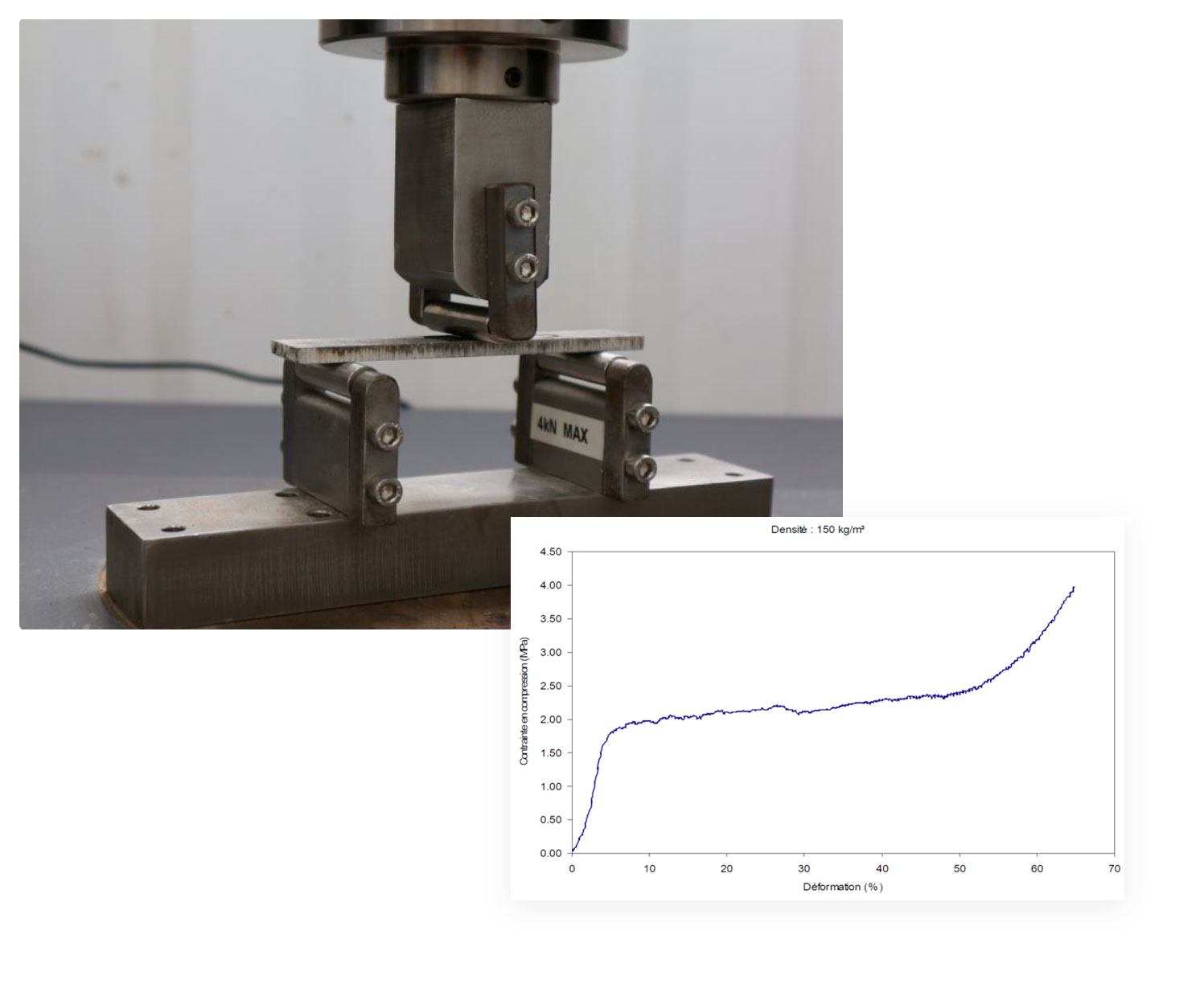

This is a rigid phenolic foam. It is used to design the damping, mechanical reinforcement, insulation and fire protection of packaging intended for the transport of sensitive materials for the nuclear and weapons industries. It is developed in partnership with the CEA.

Characteristics :

- Moulded or injected: production of parts with complex shapes and filling of large volumes and small gaps.

- A wide range of densities.

- Rigid and light material.

- Very good mechanical properties.

- Very good fire behaviour (M1 classification).

- Negligible black and toxic smoke emissions (F1 classification).

- Does not contain CFCs or HCFCs.

- Very low water vapour permeability: moisture resistant.

Compound

These are neutrophage materials that can be used for any protection that does not withstand particular thermal and mechanical stresses.

Compound ROBATEL n° 9™ and n° 10™

Made with a plaster-based binder, these neutron shielding materials can be used for applications not subjected to specific mechanical or thermal constraints. Must be poured into an encasing.

No apparent degradation when subjected to irradiation up to 1,8.1017 thermal neutrons /cm²

- Chemical composition : boron, calcium, carbon, hydrogen, oxygen, sulfur, miscellaneous

- Materials approved by : CEA, ORANO, EDF

Compound ROBATEL n° 21™ and n° 22™

Neutron shielding material based on a polyester resin binder. These materials provide a high mechanical strength with higher operating temperatures. They are generally molded into an encasing built to specified dimensions. It can be machined.

No apparent degradation when subjected to irradiation up to 1,4.1018 thermal neutrons /cm²

- Chemical composition : aluminum, boron, calcium, carbon, chlorine, hydrogen, oxygen, miscellaneous

- Materials approved by : CEA, ORANO, EDF referenced in ISO 14152 standard

- Installation at over 50 NPPs in France, China, Korea, and South Africa

Compound ROBATEL PNT3™ and PNT7™

Neutron shielding material in the form of a fine mortar, to be used for all applications subject to thermal and mechanical constraints.

- Fire classification M0

- Chemical composition : aluminum, boron, calcium, iron, hydrogen, oxygen, miscellaneous

- Materials approved by: CEA, ORANO, EDF, US Department of Energy